Green Innovation

Superior Quality

With 50 years of expertise, leading the industry toward a greener future.

Exceptional Quality

Trusted Choice

We focus on every detail to deliver exceptional metal packaging quality.

Tailored Comprehensive Solutions

GCM provides customized professional packaging solutions for you.

Can Manufacturing Expert

Top 500 Manufacturer

About

About GCM

GCM is certified by leading companies, fully quality accredited, and provides you with the most reliable can manufacturing solutions.

Origin

Since its establishment in 1973, GCM has continually improved, introducing advanced equipment and integrating expertise across machinery, electrical engineering, precision molds, chemicals, printing, and artwork. GCM has built a comprehensive one-stop service system and earned the trust of domestic and international food and beverage industries with its all-encompassing technical strength.

sustainability

GCM actively responds to environmental trends by introducing the Slim Can dry process and RTO thermal oxidizer technology, integrating green manufacturing techniques into traditional production lines. This contributes to sustainable development while offering more eco-friendly production solutions to customers.

Since 1973

Advantage

Advantage

GCM offers a wide range of aluminum can specifications, backed by rich experience that ensures stable quality, and is highly favored across various industries.

Aluminum Cans

0

types

We offer up to 55 specification options, including 25 types of cans (aluminum cans, DRD cans) and 30 different materials and forms of lids, fully meeting the diverse needs of our customers.

Market Share in Aluminum Cans

0

%

With over 30% market share in aluminum cans, GCM remains a leading force in the industry.

Professional Experience

0

Years

With 50 years of expertise in can manufacturing, GCM ensures stable technology and comprehensive pre-sale and after-sale services, earning widespread trust.

Aluminum Can Inspection

0

%

Every aluminum can undergoes 100% full inspection to ensure the highest quality standards, meeting customer expectations.

Aluminum Can Advantages

Aluminum

Can

Advantages

01

Environmental Protection & Safety

・Aluminum cans are infinitely recyclable, minimizing resource waste.

・Less likely to be mistakenly ingested by wildlife, reducing ecological risks.

・Less likely to be mistakenly ingested by wildlife, reducing ecological risks.

Aluminum Can Advantages

Aluminum

Can

Advantages

02

Flavor preservation

・Superior sealing prevents gas and light exposure, preserving freshness.

・Seamless punch-formed design ensures no leakage.

・Seamless punch-formed design ensures no leakage.

Aluminum Can Advantages

Aluminum

Can

Advantages

03

Convenience in Daily Life

・Lightweight design reduces transportation and handling costs.

・Durable and pressure-resistant packaging, convenient for storage and transport.

・Durable and pressure-resistant packaging, convenient for storage and transport.

Aluminum Can Advantages

Aluminum

Can

Advantages

04

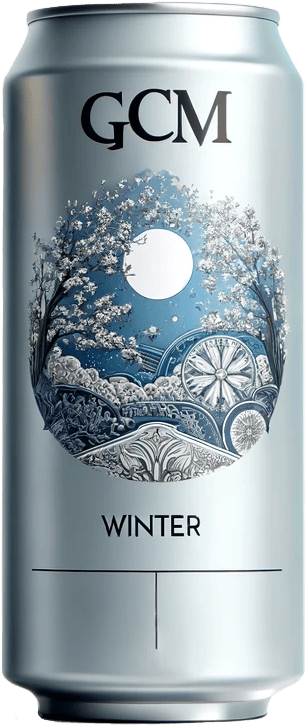

Exquisite and Aesthetic

・Beautiful glossy appearance and excellent printing effect.

・It is possible to create special shapes that are not possible with ordinary metals.

・It is possible to create special shapes that are not possible with ordinary metals.

Products

Products

Hot Products

Juice cans

Ideal for packaging a variety of beverages, including soda, juice, tea, coffee, and energy drinks, while preserving their original taste.

Canned Food Containers

Suitable for packaging vegetables, fruits, meat, seafood, and ready-to-eat meals, ensuring freshness and extended shelf life.

Pull-Ring Lids

Provides complete sealing to ensure the safety and freshness of the container’s contents.

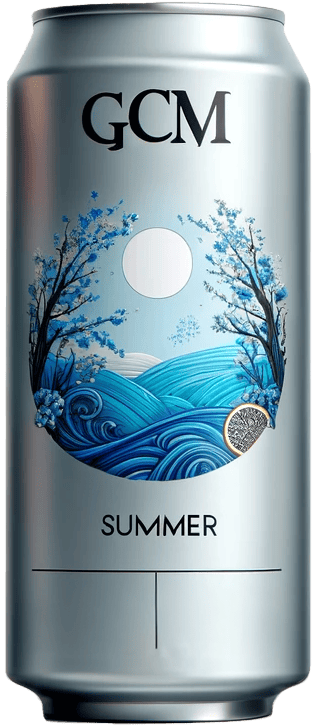

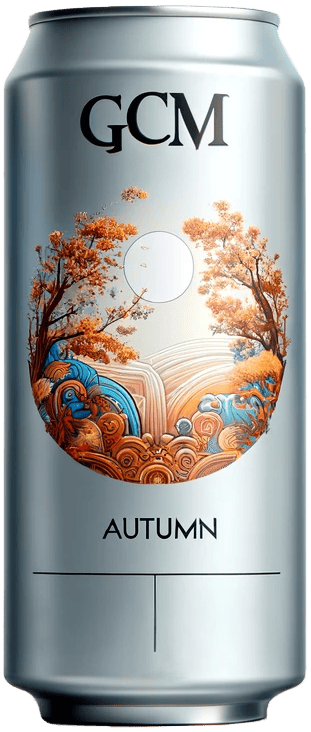

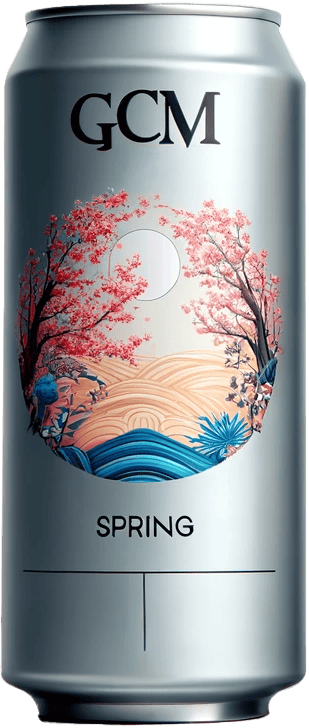

Customized Products

Provides customized aluminum can products, designed and manufactured according to the specific needs and requirements of customers.

News

News

Green Manufacturing

Aluminum cans are more than just ideal packaging for food and beverages—they are a sustainable choice for our environment. Their durable material prevents accidental ingestion by wildlife, preserving ecological balance. We actively promote green manufacturing to reduce environmental impact, working together with our customers toward a more sustainable future.

Go Green

Environmental Action

Water Resources

Waste

Air Quality

Promote water conservation

Enhancing Water

Efficiency

Water Resources

Water resources play a crucial role in GCM’s production process. We are committed to reducing water consumption and enhancing wastewater treatment efficiency to achieve more sustainable manufacturing.

Strengthen recycling

Enhance digitalization

Waste

GCM conducts annual assessments of waste output and sets progressive targets to reduce waste generation, ensuring a more environmentally friendly and sustainable production process.

Reduce Carbon Emissions

Enhance Air Quality

Air Quality

GCM prioritizes air quality management by tracking annual VOC emissions and achieving reduction targets through continuous monitoring and equipment upgrades.

Knowledge

Aluminum Can Academy

Life Cycle

Composition

Finished Can

“Closed-loop recycling” is a method for maximizing energy and resource efficiency, and aluminum beverage cans are one of the best examples of this sustainable process.

LIFE CYCLE

Recycled Cans

PROCESS

During the aluminum can manufacturing process, cutting and stamping operations generate aluminum sheet scrap (off cuts), which are systematically collected.

LIFE CYCLE

Compacted Aluminum

Compressing bulky aluminum materials is a crucial step in the recycling process. Proper handling not only significantly reduces volume but also enhances storage, transportation efficiency, and improving the subsequent smelting process.

LIFE CYCLE

Crushing

Recycling plants crush aluminum compacted into smaller granules and process them through multiple refining stages to remove impurities, ensuring the final product meets the purity requirements of the refining process.

LIFE CYCLE

Remelting

Remelting is a crucial step in converting recycled aluminum cans into reusable molten aluminum. This process is not only highly efficient but also reduces carbon emissions, making it more environmentally friendly.

LIFE CYCLE

Aluminum Ingot

After recycled aluminum cans are melted into liquid aluminum, they are cast into aluminum ingots for further processing and industrial applications.

LIFE CYCLE

Aluminum Coil

Transforming recycled aluminum cans into aluminum coils involves a series of intricate processes, including hot rolling, cold rolling, and quality inspection, to produce high-quality materials that meet requirements.

LIFE CYCLE

NEXT

Recycled Cans

Aluminum Can

Outer Layer

凡立水

保護鋁罐及其內容物

油墨印刷

假文字假文字

外層白色PET

用於抗磨耗以及促進油墨的結合附著性

內層白色PET

假文字假文字

鋁材

假文字假文字

Varnish

Protects the ink and enhances the can’s smoothness

Ink Printing

Used for can body printing

Outer White PET

Enhances abrasion resistance and ink adhesion

內層白色PET

假文字假文字

Aluminum

The primary material for the can body and lid

Aluminum Can

Inner Layer

Aluminum

The primary material for the can body and lid

Inner Transparent PET

Acts as a barrier layer

外層白色PET

作為隔離層

鋁材外層

凡立水|保護鋁罐及其內容物

油墨印刷|假文字假文字

外層白色PET|用於抗磨耗以及促進油墨的結合附著性

內層白色PET|假文字假文字

鋁材|假文字假文字

鋁材內層

鋁材|假文字假文字

內層透明PET|保護鋁罐及其內容物23423423423

外層白色PET|保護鋁罐及其內容物23423423423

Clients

Partner

GCM’s clients include renowned food and beverage companies both domestically and internationally, earning a strong reputation with guaranteed quality.

Creative Development

From concept to product, we help you create a unique beverage brand and bring your vision to life.

Other Matters

Got questions or business inquiries? Feel free to reach out—we’re happy to assist!

Join the GCM Family!

GCM is growing steadily and welcomes professionals to shape the future with us!

Unleash your potential and achieve more!