ABOUT CAN

About Aluminum Cans

How did cans come into existence?

The Origin of Canning

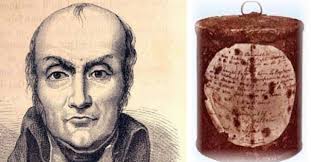

The First Canning Patent

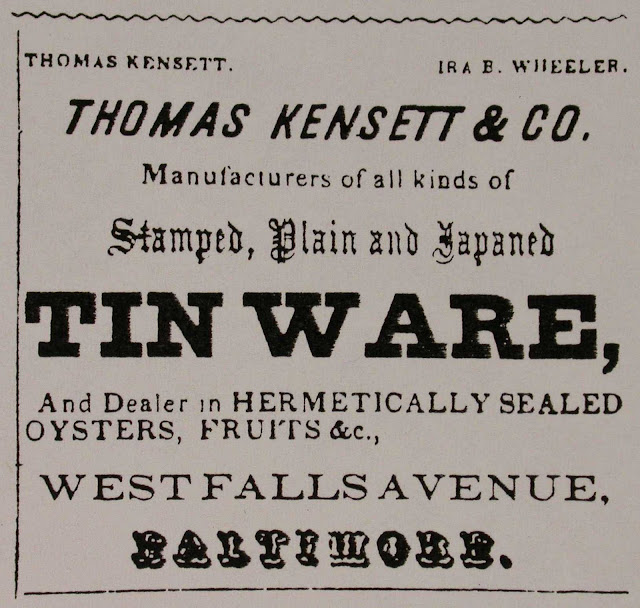

The First Canning Factory

Canned Foods Imported to America

Canned food on polar expeditions

The Invention of Canmaking Machinery

Invention of the Double Seal Method

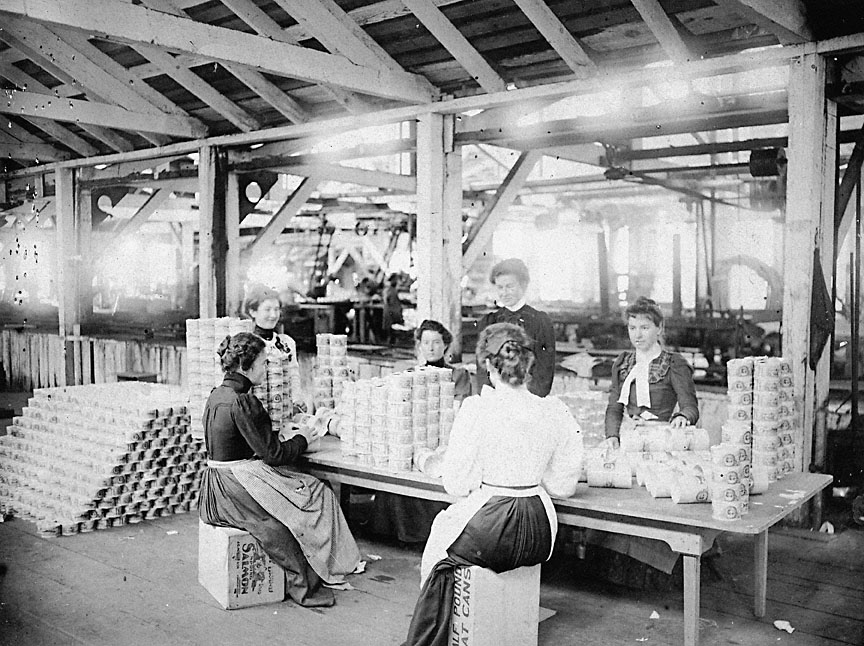

Female Canning factory Workers

Establishment of the American Can Company

“Canning Fruit” A Good Way to Preserve Produce

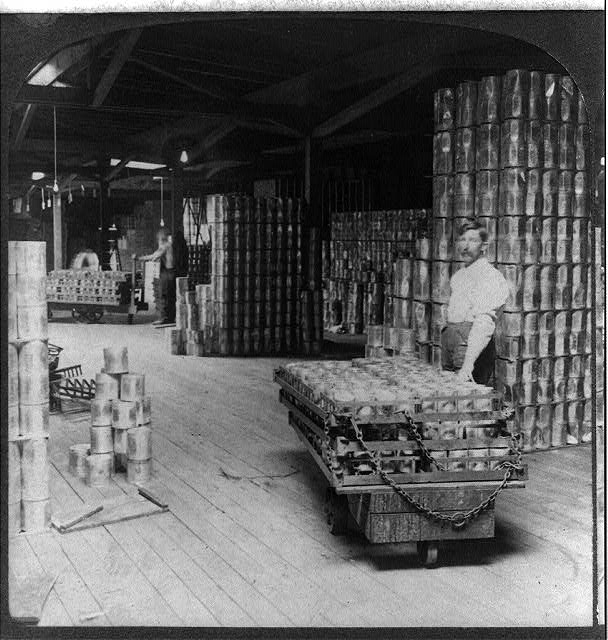

Early 20th Century Canneries

Growing Demand for Food Freshness

The Modernization of the Canning Industry

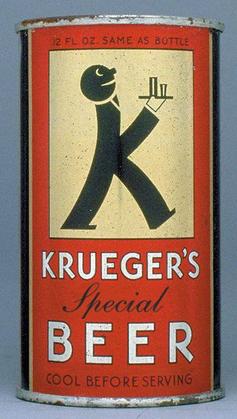

The birth of the first beer can

The Impact of the War

To maintain the supply of cans during the war, the government urged the public to recycle used cans. Citizens delivered the cans to local collection agencies, which sent them to tin removal plants. The recovered metal was partially used to produce new cans, ensuring a steady supply for both soldiers and civilians.

War drives recycling technology

The invention of aluminum cans

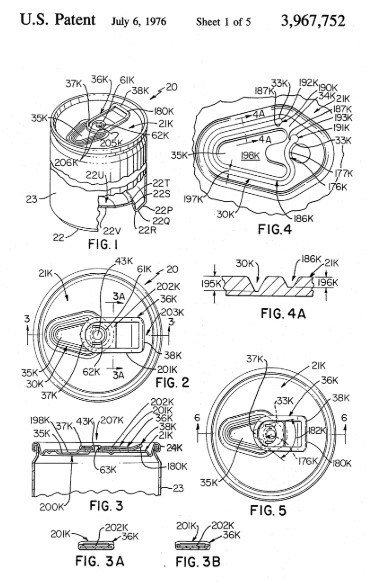

The Invention of the Pull Tab

Mass Production of Aluminum Beverage Cans

The Invention and Controversy of the Stay-On Tab

Modernization of Can Manufacturing Industry

As we enter the 21st century, awareness of environmental protection continues to rise, with sustainable resource utilization becoming a key focus across various sectors. In response, the aluminum can industry has actively promoted the lightweighting of its products. Through technological innovations, the thickness of can walls has been continuously reduced, effectively lowering the amount of raw materials used. This improvement not only cuts production costs but also reduces energy consumption during transportation, highlighting the environmental benefits.

Compared to the past, the unit weight of aluminum cans has significantly decreased, and this technological optimization is still ongoing. Aluminum possesses excellent recycling properties, with its recycling process requiring much less energy than the refining of virgin aluminum. Consequently, the aluminum can industry has begun building a robust recycling system, aiming to improve recycling efficiency. Many countries and regions have already established effective recycling mechanisms for aluminum cans and are actively encouraging consumers to participate in recycling efforts. Recycled aluminum can be used to manufacture new cans or other aluminum products, forming a sustainable circular economy that greatly reduces the consumption of natural resources.

With advancements in technology, aluminum can manufacturing has seen continuous innovation, including the introduction of high-speed production lines, the application of precision control systems, and the enhancement of printing technology. These technological breakthroughs not only improve production efficiency and lower costs but also significantly enhance product quality and aesthetics.

罐頭密封技術的開發

(21 October 1766 – 23 July 1822)

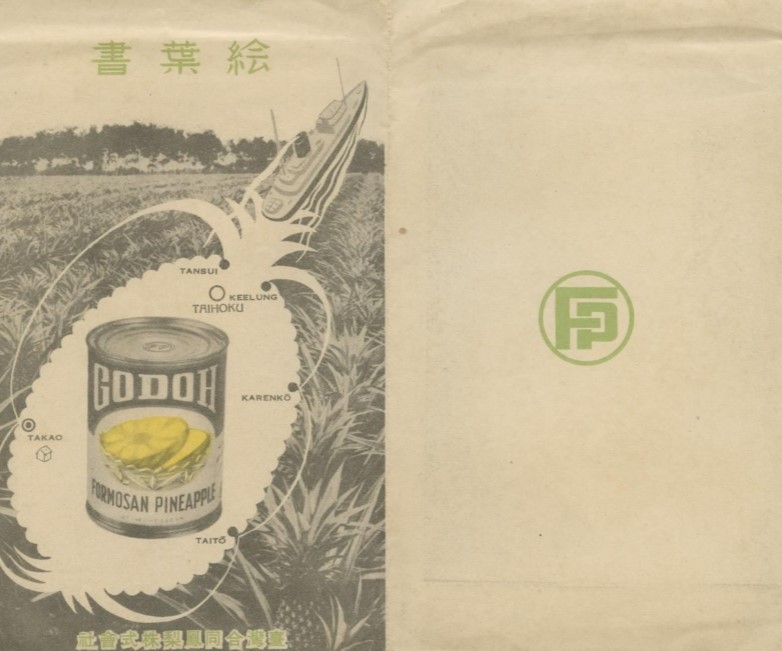

The Beginning of Taiwan's Pineapple Canning Industry

Due to the limited pineapple harvest season, Mr. Okamura built a temporary factory outside the west gate of Fengshan Street in January 1902, closer to the production area. In March of the same year, he purchased new machinery to expand production capacity and held a groundbreaking ceremony in May. This factory became the first pineapple canning factory in Taiwan—Okamura Pineapple Manufacturing Factory.

Taiwanese canneries were established

The Rise of Taiwanese Canning Factory

Taiwan's Canning Industry

Internal Competition in Taiwan's Canned Pineapple Industry

Taiwan's Food Canning Industry

Impact of the war

The Era of Taiwan's Canning Industry

Taiwan Canned Food Reaches its Peak

Great China Metal Ind. Co., Ltd. was Established.

The Origin of Aluminum Can Manufacturing in Taiwan

GCM started the high-speed aluminum can production line.

Aluminum Can Advantage

Environmental Safety

- Aluminum cans are not easily eaten by wild animals because animals cannot bite through the metal. (PET bottles, made of plastic, are very soft for animals, making it easy for them to mistakenly ingest.)

- Used aluminum cans can be 100% recycled indefinitely, processed and regenerated into aluminum ingots and then made into aluminum cans again, allowing for continuous recycling and reuse. Therefore, it is a very environmentally friendly material. In addition, most aluminum cans use eco-friendly lids, which not only make it safer to open the cans but also eliminate the need to discard the pull tabs, preventing environmental pollution.

01

Flavor preservation

- Aluminum cans are manufactured using a stamping method, and the can body has no edge seal. This not only blocks gas but also provides a longer shelf life, making it easier to preserve the flavor of beverages compared to general packaging materials.

- With excellent mechanical properties, such as high temperature resistance, humidity change resistance, and corrosion resistance, aluminum cans are also impervious to light and air. This makes them the most suitable packaging for nitrogen-filled low-acid beverages like beer, soda, fruit juices, and other carbonated drinks.

02

Convenient life

- Aluminum cans are lightweight, which helps reduce transportation and handling costs. Their packaging is also strong and unbreakable, with good pressure resistance, making them easy to store and convenient to carry, adapting well to the fast-paced lifestyle of modern society.

- Aluminum cans chill faster than other beverage containers such as PET bottles and paper packaging.

- Aluminum cans are easy to manufacture as easy-open cans, making them simple to open without the need for a can opener.

03

Exquisite beauty

- Aluminum cans have a beautiful glossy appearance, high commodity value, and are easy to print.

- Aluminum cans are easy to manufacture into special shapes that cannot be made from ordinary metals.

04

GREAT CHINA METAL

ECO(Slim) Aluminum Cans

VS

Conventional Aluminum Cans

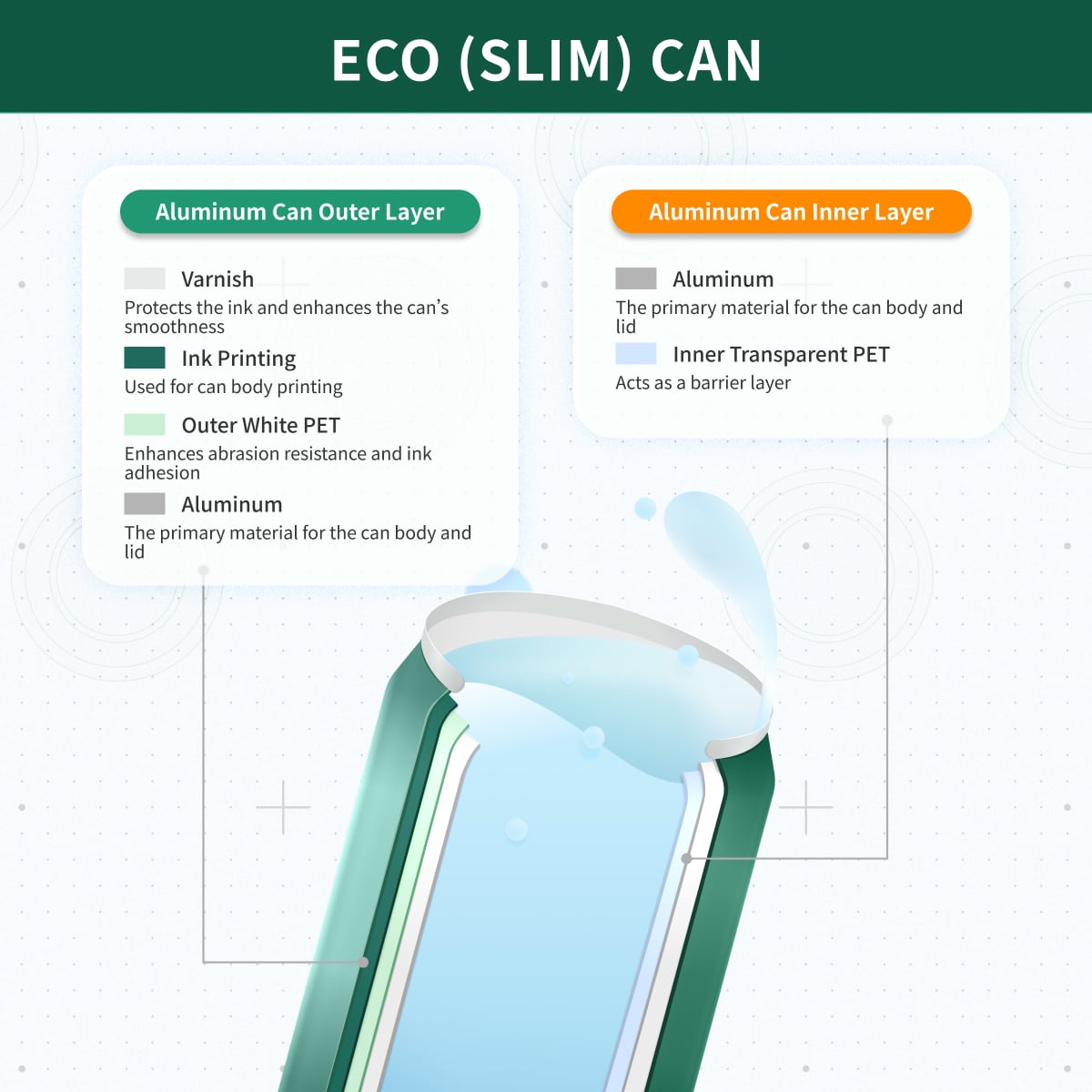

Characteristics of ECO (Slim) Aluminum Cans

Product Safety

Structural Strength

Content Preservation

Appearance

What is the difference between

aluminum cans and steel cans?

| ALUMINUM | STEEL | DESCRIPTION | |

|---|---|---|---|

| Weight | Lighter | Heavier | Aluminum is 1/3 lighter than iron, requiring less energy for transportation. |

| Rustproof | Will not rust | Prone to rust | Aluminum cans maintain the quality of the juice and beer inside for a long time without rusting or corroding. |

| Thermal conductivity | Higher | Lower | |

| Usage | Mainly used for sparkling beverages and alcoholic beverages | Steel cans are primarily used for non-carbonated drinks and food items. | |

| Ingredients | Aluminum | Tinned Steel | |

| Recycling Process | Simple | Complex | |

| Material Costs | Higher | Lower | |

| Structural Strength | Weaker | Stronger | Steel cans are less prone to deformation. |

| Magnetism | No | Yes | The best way to determine if a can is aluminum or steel is to use a magnet. If the magnet attracts the can, it's a steel can. |