Aluminum can recycling can be done better: from 33% to a 62% target.

Source: International Aluminium Institute

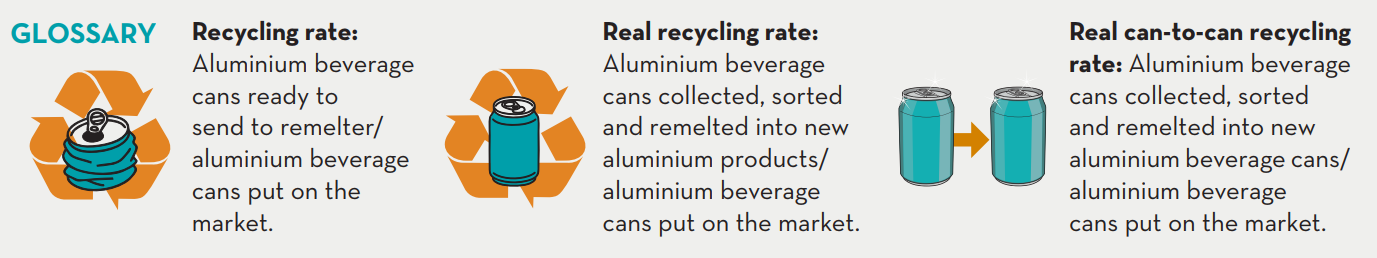

A joint study by the International Aluminium Institute (IAI) and the University of Tokyo reported that in 2019, 71% of aluminum cans worldwide were collected for recycling. While this figure appears promising, in reality, only 33% were actually recycled into new aluminum cans. Another 38% were turned into other products, and 29% were not recycled at all.

Where did the recycled aluminum cans go?

Compared with PET bottles, of which only 7% are recycled, and glass bottles at 20%, aluminum cans have a relatively higher recycling rate of 71%. However, within that 71%, the situation is as follows:

33% are recycled into new aluminum cans

38% are turned into other products (such as automotive parts and building materials)

29% are not recycled at all

Among these, 23% of aluminum cans are used to manufacture car engine parts. The issue is that the alloy composition of engine parts differs from that of beverage cans, making them unsuitable for being recycled back into new cans — a process known as “downcycling.”

Why can’t engine parts be turned back into aluminum cans?

Aluminum cans are not made of pure aluminum — they are alloys containing specific proportions of elements such as magnesium and manganese. The can body typically uses 3004 or 3104 alloys, while the can lid uses 5182 alloy.

On average, the composition of an aluminum can is approximately:

96% aluminum

1.7% magnesium

1.1% manganese

1.3% other elements

In contrast, automotive engine parts are made of alloys containing higher levels of silicon (10.5%), copper (3.5%), and nickel (1.5%). These elements alter the properties required for aluminum cans, making engine parts unsuitable for remelting into new cans.

Magnesium and manganese are listed by the European Union as critical raw materials. Once aluminum cans are downcycled into engine parts, these elements are effectively lost from the can-to-can recycling loop.

Future Development Path

The International Aluminium Institute (IAI) has set clear phased targets:

By 2030

Can-to-can recycling rate: 62%

Overall recycling rate: 71%

87% of recycled cans returned to the can-to-can loop

By 2040

Can-to-can recycling rate: 70%

Overall recycling rate: 80%

By 2050 (Vision)

Can-to-can recycling rate: 95%

Overall recycling rate: 95%

100% of recycled aluminum cans returned to the can-to-can loop

The Enormous Potential of a Circular Economy

Research shows that if the current global annual consumption of 420 billion aluminum cans continues to be recycled at the present 33% can-to-can recycling rate, by 2050 this would cumulatively produce 207 billion new cans.

However, if the rate were raised to 62%, the same amount of aluminum could yield 685 billion new cans by 2050 — more than three times the production capacity.

At an exceptional 95% recycling rate, the total output could reach nearly 6 trillion aluminum cans.

Significant Differences Across Countries

United States:

A leader in can-to-can recycling — 97% of recycled cans go back into can production,

but the overall recycling rate is only 43% (2023).

Thailand:

Outstanding performance with a 79% actual recycling rate, 72% can-to-can rate, and 91% of recycled cans returning to the can-to-can loop.

Vietnam:

High collection rate and good material quality,

but due to export-tariff restrictions, its can-to-can recycling rate is only 1%, the lowest in the world.

Implications for the Industry

This report underscores the importance of establishing a complete and efficient recycling system.

For aluminum can manufacturers and recyclers, the key lies in:

Building a stable, high-quality UBC (Used Beverage Can) supply chain

Preventing aluminum cans from being diverted to other product applications

Promoting policies that support can-to-can recycling

Considering the adoption of recycling-friendly alloy designs

As the world places increasing emphasis on circular economy and sustainability,

the aluminum can industry stands at a pivotal point of transformation.

By improving the can-to-can recycling rate, the industry can not only significantly reduce raw-material consumption but also preserve the value of critical elements such as magnesium and manganese, helping to create a more sustainable future for the next generation.