HISTORY

History & Development

1970

1980

1990

2000

2010

2020

1973

Great China Metal(GCM) Ind. Co., Ltd. was Established.

Great China Metal(GCM) Ind. Co., Ltd. was founded with a capital of NT$10 million.

1974

First Phase of Toufen Plant Expansion and Technology Upgrade

The first phase of the Toufen plant was completed, and Taiwan’s first British Crabtree two-color iron coating line was installed and put into production.

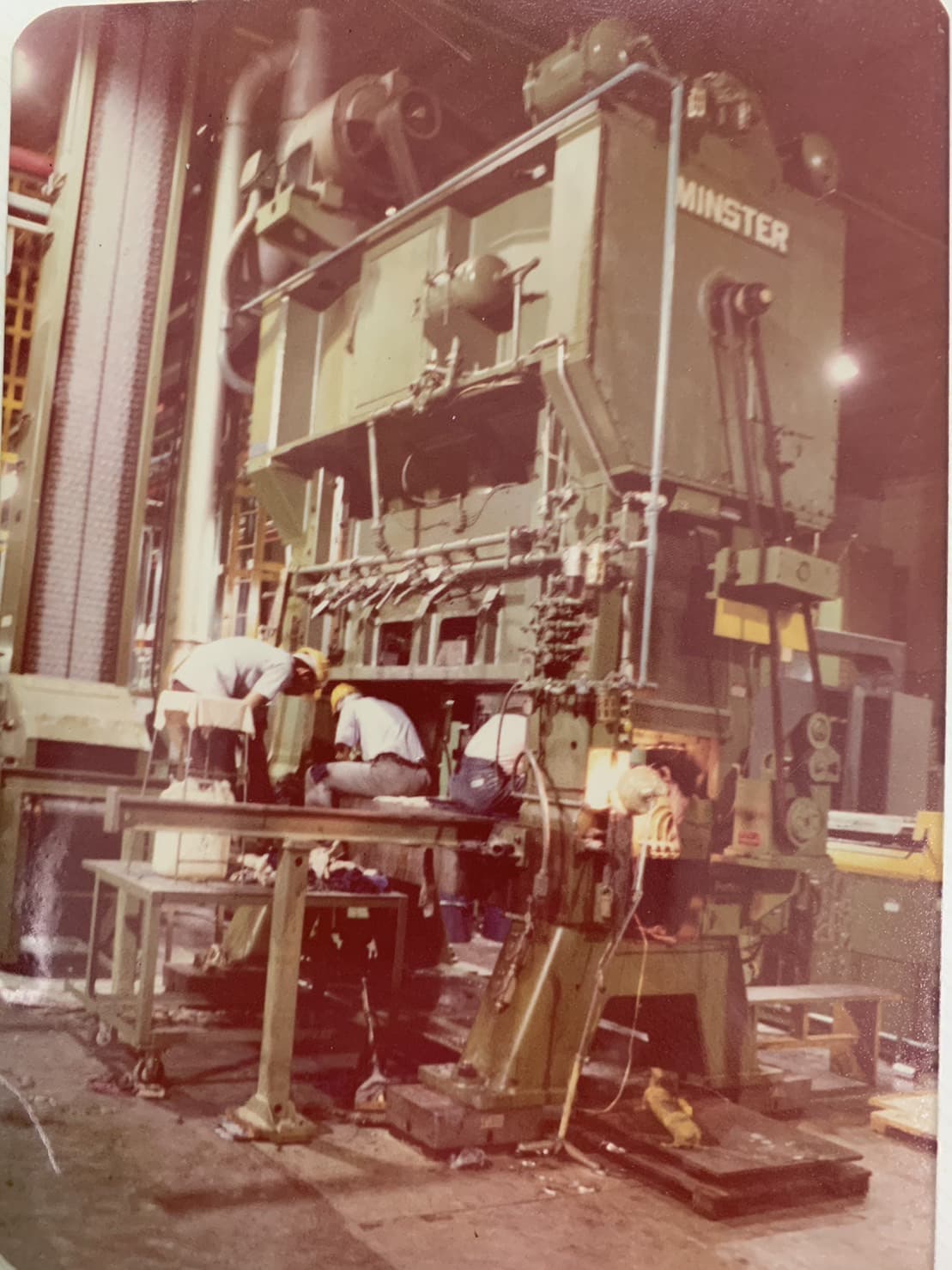

1976

Taiwan’s First Minster Combination Press Production Line—Pioneering Local Mass Production of Aluminum Easy-Open Ends

Introduced Taiwan’s first Minster combination press to produce 202 and 211 diameter aluminum easy-open covers.

1977

Taiwan’s First Swiss-Made Welded Can Production Line Officially Introduced

GCM introduced Taiwan’s first Swiss Soudronic welded can production line.

1979

Expansion of Aluminum Easy-Open End Production Lines

GCM added the 2nd, 3rd, and 4th aluminum easy-open end production lines and successfully developed the 209-diameter easy-open end mold.

1980

Collaborating with PAC to Establish a New Production Line

GCM invested US$15 million and commissioned the U.S.-based PAC Corporation to design a two-piece aluminum can production line with a speed of 800 cans per minute. It was officially put into production in 1981.

1981

Taiwan’s First High-Speed Two-Piece Aluminum Can Production Line in Operation

GCM successfully established Taiwan’s first high-speed two-piece aluminum can production line and commenced mass production.

1982

Strengthening Technical Cooperation with the U.S.

GCM signed a technical cooperation agreement with Continental Can Corporation

1985

Introducing German Equipment and Developing Variable Printing Technology

GCM introduced a two-piece extrusion can system from Alfonshaar, Germany, successfully implementing variable printing technology and bringing more diverse packaging designs to the Taiwanese market.

1986

Development of multiple production lines and significant increase in production capacity

GCM added multiple production lines

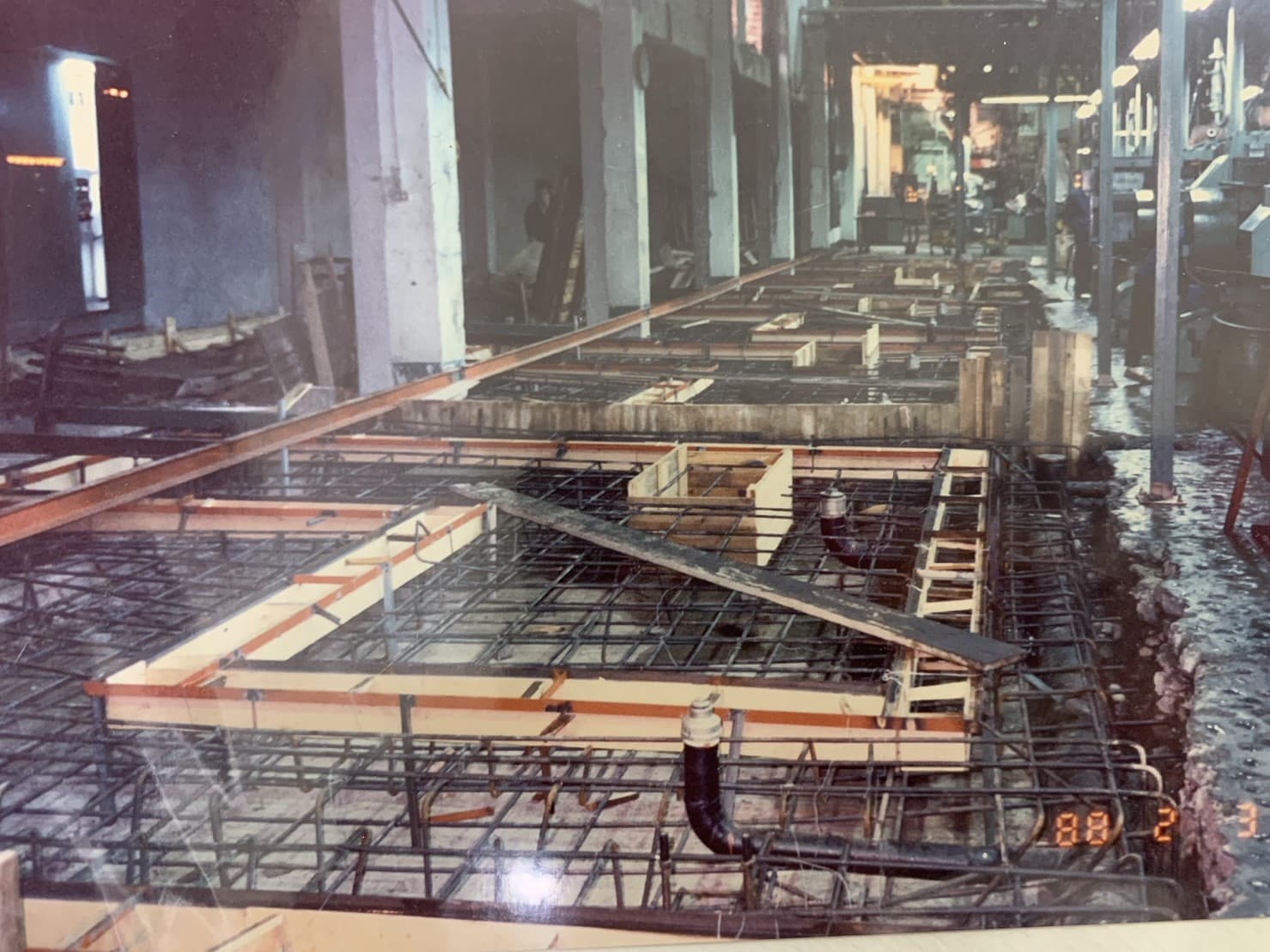

1987

Completion of the Second Aluminum Can Production Line and Successful Production of 206-Diameter Easy-Open Caps

GCM added the second two-piece aluminum can production line and the 206-diameter easy-open cap production line.

1989

The New Production Line for 307 and 301 Diameters with Full Open Covers is Officially Launched

GCM added the 307 and 301 diameter full open cover production line and officially began production.

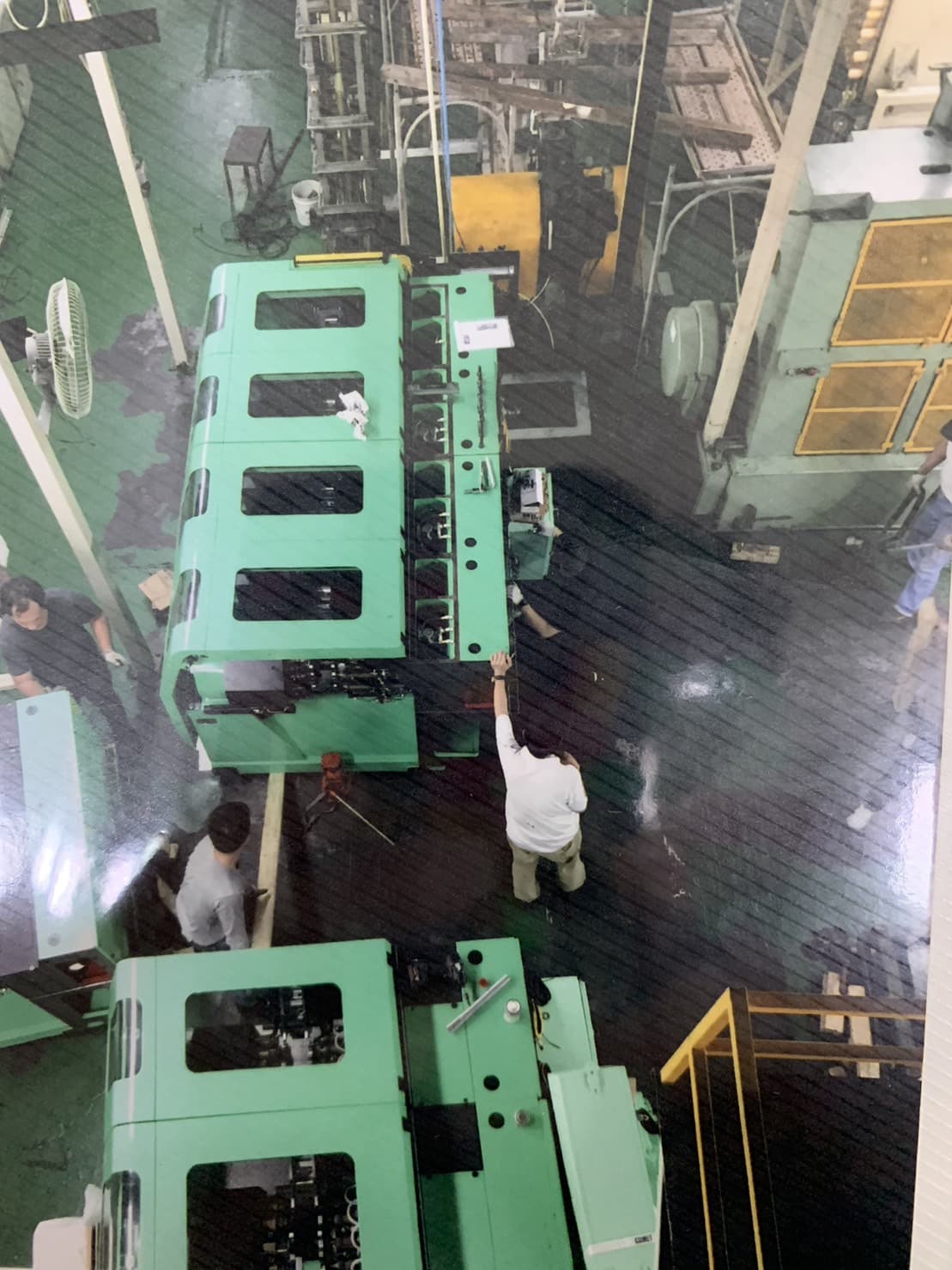

1990

Stocks Officially Listed, Entering a New Stage of Development

GCM’s stock was officially listed on August 8, 1990, as a Class I stock.

1990

Large Two-Piece Aluminum Can Production Line Successfully Test Run

The installation and test run of the 946cc and 500cc large two-piece aluminum can production lines have been completed.

1991

209 Diameter Aluminum Full Open Cap Technology Successfully Developed

Successfully developed and officially began production of the 209 diameter aluminum full open cap.

1992

Aluminum Can Production Rate Reaches Record High

The production capacity of the second aluminum can production line was expanded to 1,600 cans per minute.

1993

Successfully Set Up Production Line for 250ml Aluminum Cans and Started Mass Production

Successfully set up the 250ml aluminum can production line and entered mass production.

1993

High-speed SOT Production Line Exceeded 5 Million Pieces per Day

In response to the government’s environmental protection policy, a high-speed eco-friendly cover (SOT) production line was introduced with a daily production of 5 million pieces (206 diameter), completing the trial run and officially starting production.

1994

Toufen Plant was Awarded ISO 9002 Quality Certification

Toufen Plant successfully passed the ISO 9002 quality certification by the Bureau of Commodity Inspection and Quarantine.

1995

Fugang Plant was awarded ISO 9002 quality certification.

Fugang Plant has passed the ISO 9002 quality certification by Bureau of Commodity Inspection and Quarantine.

1995

Shanghai United Can Co., Ltd. officially opened for business.

Invested and established Shanghai United Can Co., Ltd. in Shanghai, completed in June, and started trial production.

1997

Focusing on LLDPE Stretch Film Technology, Huatong United Plastics Industry Co. Ltd. officially started production.

Invested and established Huatong United Plastics Industry Co., Ltd. in Haimen, Jiangsu Province to produce LLDPE Stretch Film and set up the first production line.

1998

Capital Expansion to NT$3.05 Billion

Capital increased to NT$3,050 million by capitalization of surplus.

2001

Huatong United Plastics Industry Co., Ltd. successfully expanded its second production line.

The subsidiary, Huatong United Plastics Industry Co., Ltd., added a second production line for LLDPE Stretch Film. Participated in the Cannex exhibition in the United States.

2004

Vietnam production base officially completed

GCM invested and established “GCM Packaging Co., Ltd.” in Vietnam, focusing on the production of SOT eco-friendly lids.

2006

JGCM partners with Toyo Can to commence production at Chongqing United Can.

GCM’s subsidiary, Huatong United Plastics Industry Co., Ltd., added a third production line for LLDPE Stretch Film.

2007

Chongqing United Can Co., Ltd. was officially established.

GCM’s subsidiary, Shanghai United Can Co., Ltd., partnered with Nippon Toyo Seikan Co., Ltd. to jointly establish Chongqing United Can Co., Ltd., with production successfully starting in August.

2009

Jinan United Can Co., Ltd. was officially established.

Jinan United Can Co., Ltd. was established in Jinan, Shandong Province, to install two aluminum can production lines, with production scheduled to begin in the fourth quarter of 2010.

2011

Completion of the warehouse expansion project at the Toufen Plant.

Construction of an additional warehouse to the south of the Toufen Plant.

2012

Huatong United expands with a fourth production line and printing equipment upgrade at the Toufen plant.

Subsidiary Huatong United Plastics Industry Co., Ltd. installed a fourth production line for LLDPE stretch film. The Toufen plant introduced a new 8-color printing machine, while the Fugang plant carried out compartmentalization for a 3-color printing machine.

2014

Strengthening the Strategic Partnership with Toyo Seikan

GCM signed a cooperation agreement with Toyo Seikan.

2015

Introduction of Fuji's Three-Color Metal Printing Line

GCM purchased and installed Fuji’s three-color metal printing line to replace the old equipment. The shrink-head flanging machine installation at the Toufen plant was also completed.

2016

Innovating for Sustainability: Launch of Eco-Friendly Aluminum-Coated Can Technology

GCM established an aluminum-coated can factory and introduced Toyo Seikan’s aTULC aluminum can patented technology.

2016

Huatong United's Fifth Production Line Begins Operation

Huatong United Plastics Industry Co., Ltd. added a fifth production line for LLDPE stretch film.

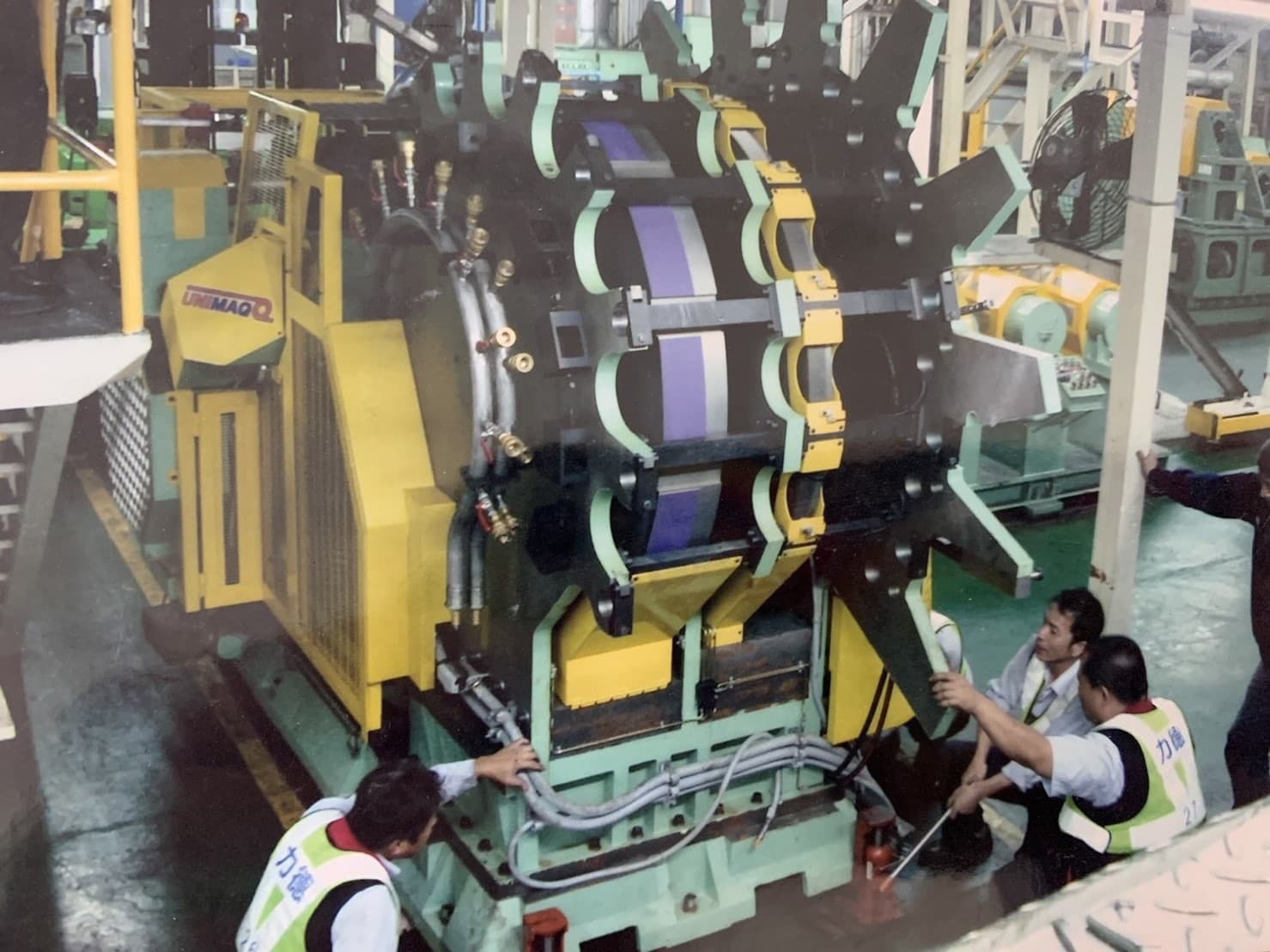

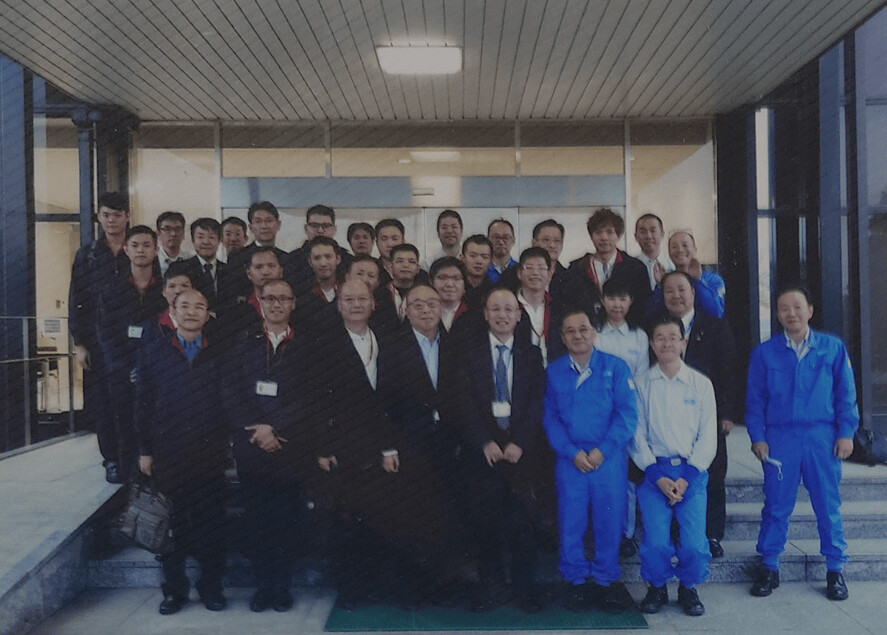

2017

Technical Exchange with Nippon Kokusai Can

In November 2017, the engineering and technical team visited Japan for a technical exchange with Nippon Kokusai Can.

2018

Investment in Foshan Sanshui Strong United Containers Co.

Huatong United Plastics Industry Co., Ltd. invested in and acquired a 30% stake in Foshan Sanshui Strong United Containers Co.

2018

Installation of Fuji’s Two-Color Metal Printing Line

Purchased and installed a second two-color metal printing line from Fuji, Japan, which was successfully commissioned and put into operation.

2019

Sustainable Upgrade! RTO Environmental System Activated, Continuous Process Optimization

The Toufen plant installed an RTO (Regenerative Thermal Oxidizer) system and a new shrink-head flanging machine. The RTO system effectively purifies process gases, eliminating volatile organic compounds (VOCs) and demonstrating superior environmental performance. Meanwhile, the new shrink-head flanging machine enhances mold precision and process stability, further improving product quality.

2020

Fugang Plant Implements Advanced Pollution Control Technology

Completion of the Fluidized Bed Pollution Control Facility at Fugang Plant

2021

Completion of DRD Line Oven Equipment Modification at Fugang Plant

DRD Line Oven Equipment Modification at Fugang Plant

2022

Completion of the Sixth Production Line at Huatong United Plastics Co.

Our subsidiary, Huatong United Plastics Industry Co., Ltd., has completed the construction of its sixth production line for LLDPE stretch film.

2023

GCM's 50th Anniversary

Over the past 50 years, we have adhered to the principle of integrity, focusing on running our business and expanding the market for our partners, while providing consumers with better products. We avoid debt and stock speculation, and have maintained stable revenue over the years. We promise our employees no layoffs, no unpaid leave, and a well-established, legally compliant retirement system. Moving forward, we will continue to uphold our tradition of excellence, offer outstanding after-sales service to our customers, create substantial returns for our shareholders, and build a friendlier working environment for our partners. We aim to become an enviable and happy company.

2024

Chongqing United Can Manufacturing Co., Ltd. Completes Solar Panel Project

Chongqing United Can Manufacturing Co., Ltd. has completed the installation of a solar panel power generation system on the roof of its plant, marking an important step for GCM on the path of green transformation.

2025

new official website is now online

With a commitment to advancement and innovation, our entirely new official website is officially launched. In alignment with digital transformation, we have developed a convenient, practical, and intuitive digital platform. The redesigned website incorporates contemporary aesthetics and a user-centric interface, with the aim of delivering a superior service experience.