Organizational Structure and Department Responsibilities

Organizational Structure

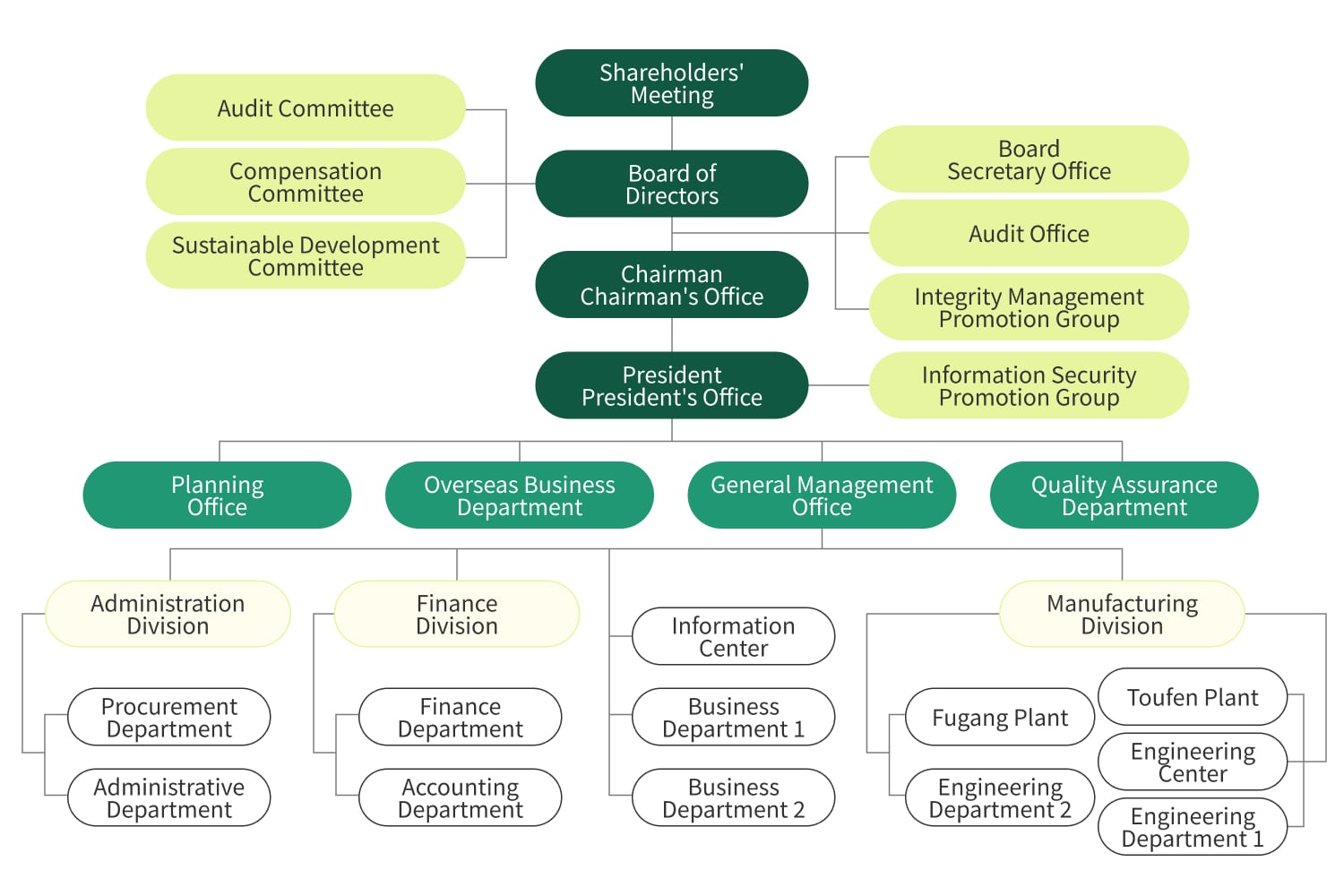

Organizational Chart

Department Responsibilities

| Department | Responsibilities |

|---|---|

| General Management Division | 1. Formulation and tracking of company business goals. 2. Management of accounting, financial, and stock affairs operations. 3. Internal control auditing and execution. 4. Development and execution of management regulations and welfare policies. 5. Execution of domestic and international procurement and import/export operations. 6. Development, supervision, and execution of domestic and international business operations and plans. 7. Development of business plans, market development, and performance analysis. 8. Planning, promotion, improvement of operational procedures, and maintenance of IT systems and hardware/software. 9. Establishment, utilization, and management of information system databases. |

| Quality Assurance Department | 1. Development, implementation, and inspection of quality standards. 2. Research and improvement of quality inspection systems and development plans. 3. Establishment and supervision of self-inspection processes. 4. Management of process capability analysis (SPC). 5. Implementation of quality inspections to ensure customer confidence. |

| Engineering Department | 1. Execution and supervision of production equipment technical management. 2. Planning, execution, and supervision of equipment maintenance and repair. 3. Equipment efficiency analysis, troubleshooting, and improvement plans. 4. Planning, execution, and supervision of technical personnel training. 5. Management, improvement, and evaluation of molds and spare parts. 6. Execution and analysis of process technology, settings, and special projects. 7. Revision and management of technical documents and blueprints. 8. Development and execution of new manufacturing processes. 9. Technical support and manpower assistance. |

| Toufen Plant | 1. Setting production targets based on business strategies and executing plans. 2. Production and raw material/product management of aluminum and steel cans. 3. Management of production processes and product quality improvements. 4. Management and maintenance of equipment, assets, and various resources. 5. Process improvement to enhance automation, increase production efficiency, and reduce labor costs. 6. Compliance with local government regulations and maintenance of factory safety and hygiene. |

| Fugang Plant | 1. Setting production targets based on business strategies and executing plans. 2. Production and management of raw materials and finished products for various types of easy-open ends, coating, and printing. 3. Production and management of raw materials and finished products for various types of deep-drawn cans and laminated aluminum cans. 4. Management of production processes and product quality improvements. 5. Management and maintenance of equipment, assets, and various resources. 6. Process improvement to enhance automation, increase production efficiency, and reduce labor costs. 7. Compliance with local government regulations and maintenance of factory safety and hygiene. |