Climate Change Management & Greenhouse Gas Inventory

Climate Change Risk and Opportunity Assessment

According to the “Global Risks Report” published by the World Economic Forum (WEF) in 2022, climate action failure has risen to the top of perceived global risks, followed closely by extreme weather. This highlights climate change as a severe challenge that must be collectively addressed worldwide. To implement climate risk management, reduce potential risks that GCM may face in the future, and comply with regulatory requirements, the Company has actively adopted the Task Force on Climate-related Financial Disclosures (TCFD) framework.

By structuring disclosures around the four core elements of TCFD—Governance, Strategy, Risk Management, and Metrics & Targets—the Company systematically discloses information on its climate change response. This enables GCM to address transition risks, physical risks, and emerging opportunities associated with climate change.

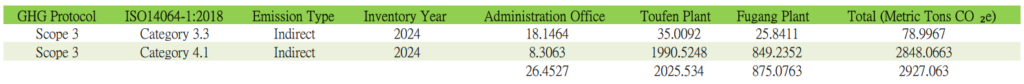

| Risk and Opportunity Categories | Detailed Explanation of Risk and Opportunity Assessment | |

|---|---|---|

| RISK | Increased Extreme Weather Events | Evaluate the impact of extreme weather on production, transportation, equipment usage, and energy supply. |

| Long-term Climate Change Impacts | Assess the hazards posed by long-term climate changes such as rising average temperatures and sea levels to the company. | |

| Policy and Regulatory Risks | Consider the potential increase in operational costs and impacts on the company due to future environmental regulations, carbon taxes, carbon fees, and renewable energy-related regulations. | |

| Market Demand Shift Risks | Evaluate the transitional risks associated with outdated processes and technologies, changing market demands, and heightened customer expectations that create operational pressures for GCM. | |

| Reputation Risk | Evaluate the risks of insufficient sustainable development efforts that may reduce stakeholder attention and investment willingness. | |

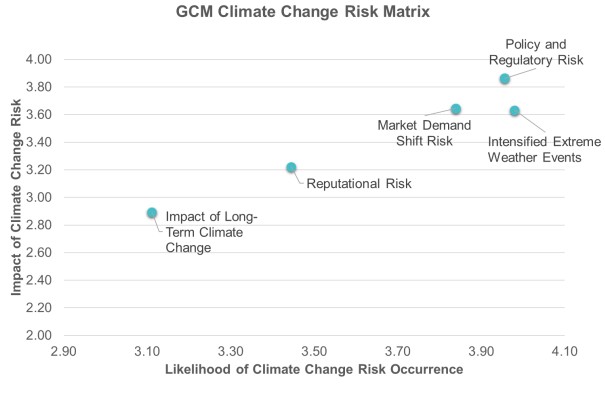

| Opportunity | Low-carbon Product Development | Develop new products to align with future market trends. |

| Energy Efficiency Improvement | Implement measures to use and recycle water resources, energy, and raw materials efficiently to save operational costs and enhance production efficiency. | |

| Investor Relations | Continue promoting sustainable practices to increase stakeholder investment willingness. | |

| Use of Renewable Energy | Early adoption of renewable energy to receive government incentives and reduce carbon emissions. | |

| Supplier Sustainability and Stability | Audit and guide suppliers, and establish standards for them to stabilize the supply chain. | |

Greenhouse Gas Reduction Management Policy

To demonstrate our commitment to carbon reduction, this policy is scheduled to be formally submitted to the Board of Directors for review in 2025, following thorough internal discussion and evaluation. The following is GCM’s preliminary draft of the Greenhouse Gas Reduction Management Policy, which outlines reduction targets, implementation measures, and progress tracking. Relevant updates will be regularly disclosed through public platforms such as our Sustainability Report and corporate website.

In recent years, greenhouse gas emissions have become a focal concern for governments and corporations worldwide, as the planet faces unprecedented climate and environmental challenges. At Great China Metal (GCM), we firmly believe that harmonious coexistence with society and the environment is essential for long-term business sustainability. In an era of increasingly stringent carbon regulations, we have adopted environmental sustainability as a core corporate value, actively seeking new opportunities for sustainable development.

While strengthening our core business, we are also committed to complying with environmental regulations and meeting customer requirements. We embrace the 3R principles—Reduce, Reuse, and Recycle—to help build a better living environment for future generations. Sustainability is a long-term mission for us, and we continuously support environmental initiatives by formulating comprehensive medium- and long-term strategies to fulfill our corporate social responsibility and contribute to global sustainable development goals.

GCM pledges to follow international greenhouse gas inventory standards for emissions data analysis and will commission third-party professionals to verify the results. These verified data will serve as a solid foundation for the formulation and implementation of future improvement measures. We will continue to promote energy-saving, carbon-reduction, and environmentally friendly policies, upholding our commitment to sustainable development and fulfilling our duties as a responsible global corporate citizen.

I. Reduction Targets

Continuously implement energy-saving programs with the goal of reducing electricity consumption by 1% annually.

By 2030: Using 2022 as the base year and defining the boundaries as the Administration Office, Toufen Plant, and Fugang Plant, including Scope 1 and Scope 2 emissions, GCM aims to reduce carbon emission intensity or total emissions by 10%.

II. Implementation Measures

1. Energy Efficiency Improvement

Introduce high-efficiency energy-saving equipment.

Promote energy management systems with regular inspections and efficiency optimizations.

2. Renewable Energy Integration

Evaluate and plan the installation of solar photovoltaic systems and energy storage systems.

3. Circular Economy and Resource Efficiency

Strengthen waste reduction and resource recycling to lower greenhouse gas emissions during production.

Improve raw material utilization to reduce process-related waste.

4. Technological Innovation and Process Optimization

Continuously research and adopt low-carbon and energy-saving technologies.

Optimize process management to reduce energy and raw material consumption during production.

5. Employee Engagement and Training

Regularly conduct employee training on environmental sustainability to enhance awareness and practical ability in energy conservation and carbon reduction.

III. Progress and Outcomes

Conduct annual GHG inventories and disclose data publicly.

Establish an internal carbon management information system to track progress toward emission reduction goals.

Review reduction targets and implementation results each year and adjust strategies as needed to ensure targets are met.

Energy-saving projects in 2024:

One 100HP variable frequency air compressor

Estimated annual electricity savings: 58,570 kWhOne 100HP low-pressure, high-cooling induction motor

Estimated annual electricity savings: 3,148 kWhFull LED lighting retrofit for the Administration Office building

Estimated annual electricity savings: 35,486 kWh

Greenhouse Gas Inventory

In accordance with the “Corporate Sustainability Best Practice Principles for TWSE/TPEx Listed Companies,” GCM has established a Greenhouse Gas Inventory Task Force, authorized by the Board of Directors. The General Manager of the executive team serves as the management representative, while relevant responsible departments form a project team to oversee both internal and external information management related to the company’s sustainability and greenhouse gas (GHG) inventory. This task force is responsible for completing the company’s GHG inventory and verification work. The GHG Inventory Task Force reports its implementation plans and outcomes to the Board of Directors at least once annually. Additionally, the Board of Directors receives quarterly briefings from the task force, offering timely advice and guidance on the GHG roadmap, personnel training, and team responsibilities, thereby enhancing the Board’s functions through well-established organizational structures and mechanisms.

Regarding the GHG inventory:

Direct greenhouse gas emissions (Scope 1) refer to emissions from sources that are owned or controlled within the organizational boundary of the company. These include sources such as emergency generators, company vehicles, septic tanks, fire extinguishers, and refrigerant leakage.

Energy indirect greenhouse gas emissions (Scope 2) refer to indirect GHG emissions resulting from the consumption of imported electricity from outside the company’s organizational boundary.

All departments conduct GHG inventory activities in compliance with national policies and regulations, quantifying emissions from both Scope 1 and Scope 2. The company adopts the Global Warming Potential (GWP) 100-year values published in the IPCC Sixth Assessment Report for calculating Scope 1 emissions.

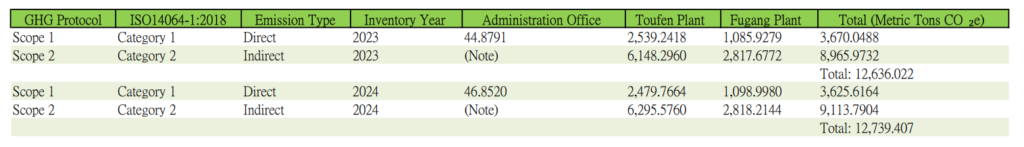

In 2024, GCM’s total Scope 1 GHG emissions amounted to 3,625.6164 metric tons of CO₂ equivalent (tCO₂e), nearly 100% of which originated from operational sites subject to emission control regulations. Although some emissions fall outside of direct regulatory scope, they are still managed and reduced through the company’s internal energy efficiency programs.

Scope 1 Emissions Management Strategy and Implementation of Reduction Targets

In response to climate change risks and in alignment with domestic and international carbon governance trends, the company has formulated a specific Scope 1 greenhouse gas (GHG) emission reduction strategy. These strategies are categorized into short-term and long-term plans and actions, aimed at gradually reducing direct emissions from operational activities.

🔹 Short-Term Strategies and Actions (1–3 years)

Energy Efficiency Improvement

Introduce high-efficiency energy-saving equipment and improve the performance of existing energy-consuming equipment.

Promote the establishment of an Energy Management System (EMS), with regular monitoring and optimization of energy use efficiency.

Circular Economy and Resource Efficiency

Strengthen waste segregation and reduction measures to enhance resource recovery rates.

Improve raw material utilization to reduce offcuts and waste generated during production processes.

Employee Engagement and Training

Conduct regular training courses on environmental sustainability and energy conservation/carbon reduction to enhance employees’ awareness and ability to take action.

🔹 Long-Term Strategies and Actions (3–10 years)

Renewable Energy Adoption

Assess and plan for the installation of solar photovoltaic systems and energy storage systems to increase the proportion of in-house green electricity.

Explore the adoption of Power Purchase Agreements (PPAs) or renewable energy certificate mechanisms.

Technological Innovation and Process Optimization

Continue investing in the research, development, and adoption of low-carbon processes and energy-saving equipment.

Optimize process management and design to reduce total energy and raw material consumption and enhance unit output efficiency.

The following are the GHG inventory data for the Administration Office, Toufen Plant, and Fugang Plant for the years 2023 to 2024:

Notes:

Global Warming Potential (GWP) values are cited from the IPCC Sixth Assessment Report, 2021.

Emission factor data sources:

(1) Direct greenhouse gas emissions: Greenhouse Gas Emission Factor Management Table version 6.0.4, published by the Environmental Protection Administration (EPA), Executive Yuan.

(2) Indirect greenhouse gas emissions: Electricity emission factors are based on data from the Bureau of Energy, Ministry of Economic Affairs—0.494 kg CO₂e/kWh for 2023 and 0.474 kg CO₂e/kWh for 2024.

The organizational boundary for the inventory includes the Administration Office, Toufen Plant, and Fugang Plant.

The organizational boundary is defined using the “Operational Control Approach,” and the inventory covers emissions of the seven greenhouse gases specified in ISO 14064: carbon dioxide (CO₂), methane (CH₄), nitrous oxide (N₂O), nitrogen trifluoride (NF₃), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), and sulfur hexafluoride (SF₆).

Since the Administration Office is leased from CHINA CAN PRINTING & METAL MFG. CO., LTD., and the building is owned by that company, with electricity costs included in the rent, its carbon emissions are accounted for under CHINA CAN PRINTING & METAL MFG. CO., LTD.

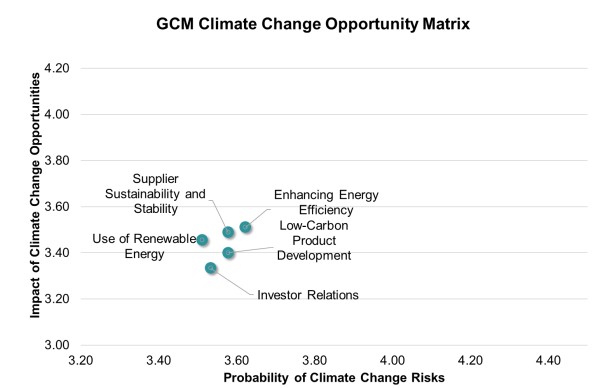

Scope 3 Greenhouse Gas Inventory

To support the implementation of Scope 3 greenhouse gas (GHG) inventory efforts, the company has completed the inventory of the following categories:

Category 3: Indirect GHG emissions from transportation (3.3 Employee commuting)

Category 4: Indirect GHG emissions from products used by the organization (4.1 Life cycle emissions from purchased energy—electricity and fuel—not included in Categories 1 and 2)

The organizational boundary covers the Administration Office, Toufen Plant, and Fugang Plant. The total Scope 3 GHG emissions for the year 2024 are calculated at 2,927.063 metric tons of CO₂ equivalent (CO₂e).