Supplier Management

To strengthen its innovation and R&D capabilities, GCM continues to advance technological development and enhance equipment capacity and efficiency across all product lines. At the same time, the company actively demonstrates its commitment to local procurement and green purchasing initiatives.

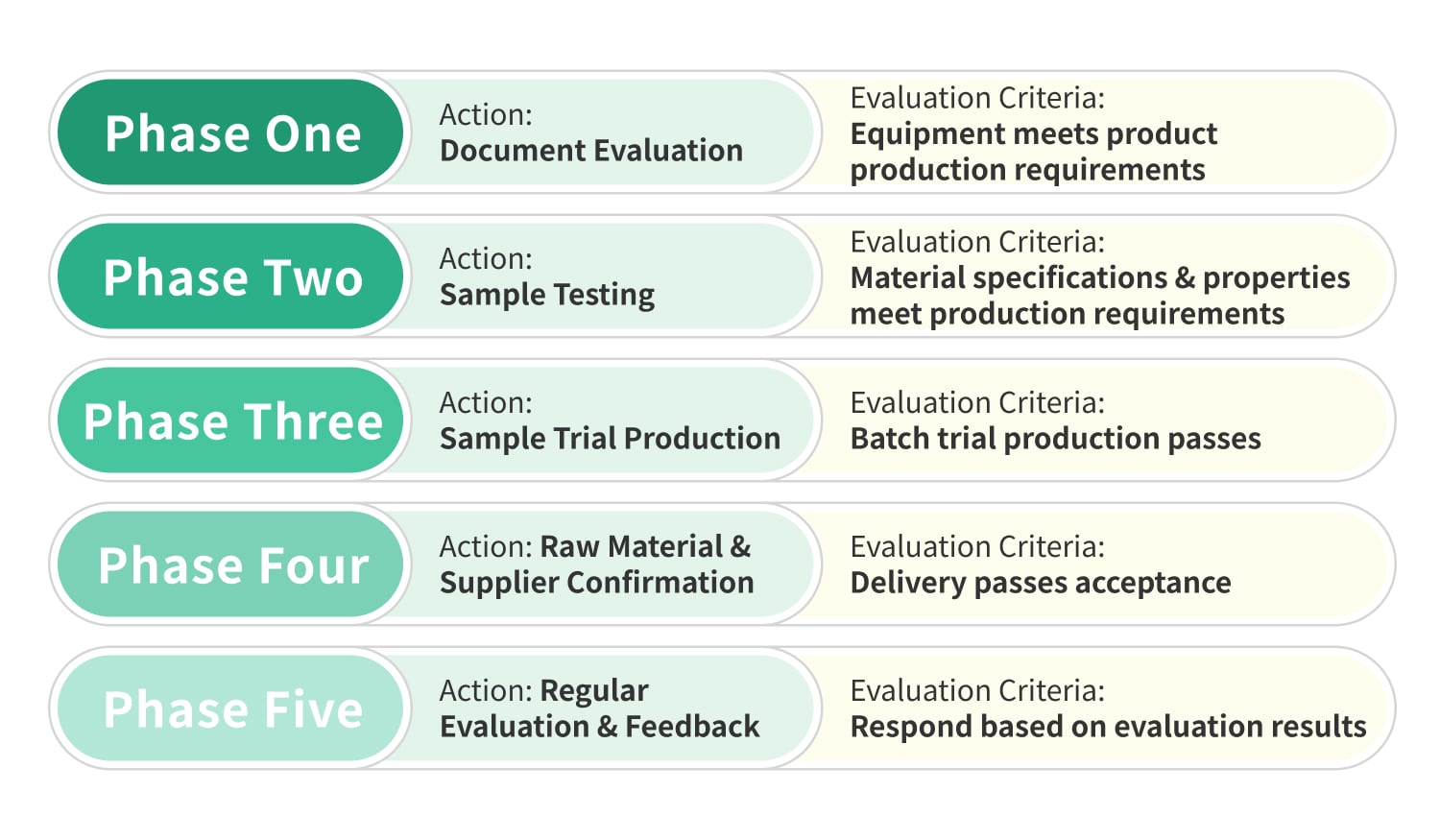

In the short term, GCM aims to ensure that suppliers consistently meet quality, delivery, and quantity requirements to support production needs and maintain competitive product pricing. In the medium term, the company will develop new suppliers to secure stable secondary sources of supply. In the long term, GCM will align with corporate policies on energy conservation, carbon reduction, and sustainable operations by developing equipment with circular economy benefits and promoting collaborative strategies with suppliers.

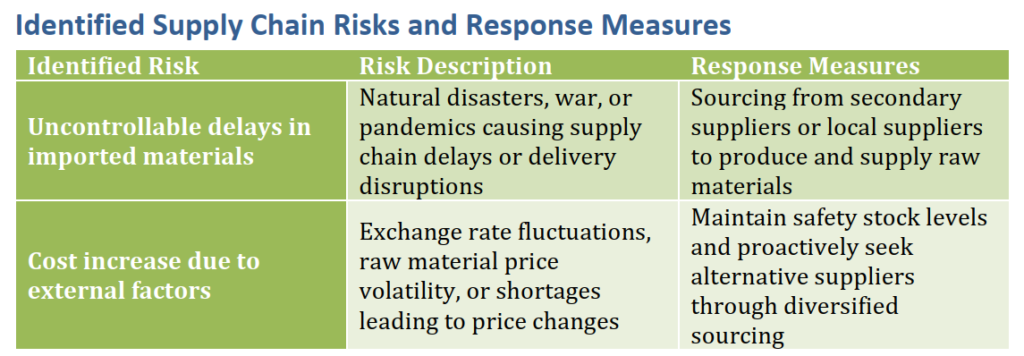

In terms of supplier risk management, GCM implements a planned production model to ensure that bottle and can production volumes, workforce allocation, material planning, and safety stock levels are all properly arranged. This approach helps minimize risks such as delivery delays, unexpected natural disasters, or human-induced disruptions that could prevent the company from meeting customer expectations.

To further strengthen operational resilience, GCM continuously identifies potential risks related to various issues, aiming to ensure effective risk management and maintain business continuity in the face of unforeseen events.

Green Supply Chain

In supplier management, GCM is committed to working hand-in-hand with its supply chain partners to fulfill corporate social responsibility and serve as strong mutual support. As a result, the supply chain has remained stable over the long term, with minimal disruptions.

In response to growing environmental concerns, GCM continuously seeks environmentally and socially friendly alternative materials. One such initiative is the use of laminated steel to replace conventional tinplate, thereby optimizing existing manufacturing processes. This approach not only reduces environmental impact but also provides better protection for packaged contents.

Additionally, GCM has replaced traditional lacquer barrels used for raw material storage with GOODPACK containers and collaborates with domestic partners for the recycling and reuse of steel drums. This initiative reduces the cost of raw material packaging and lowers the carbon footprint and logistics costs during transportation, demonstrating the company’s strong commitment to green practices.