Product Quality

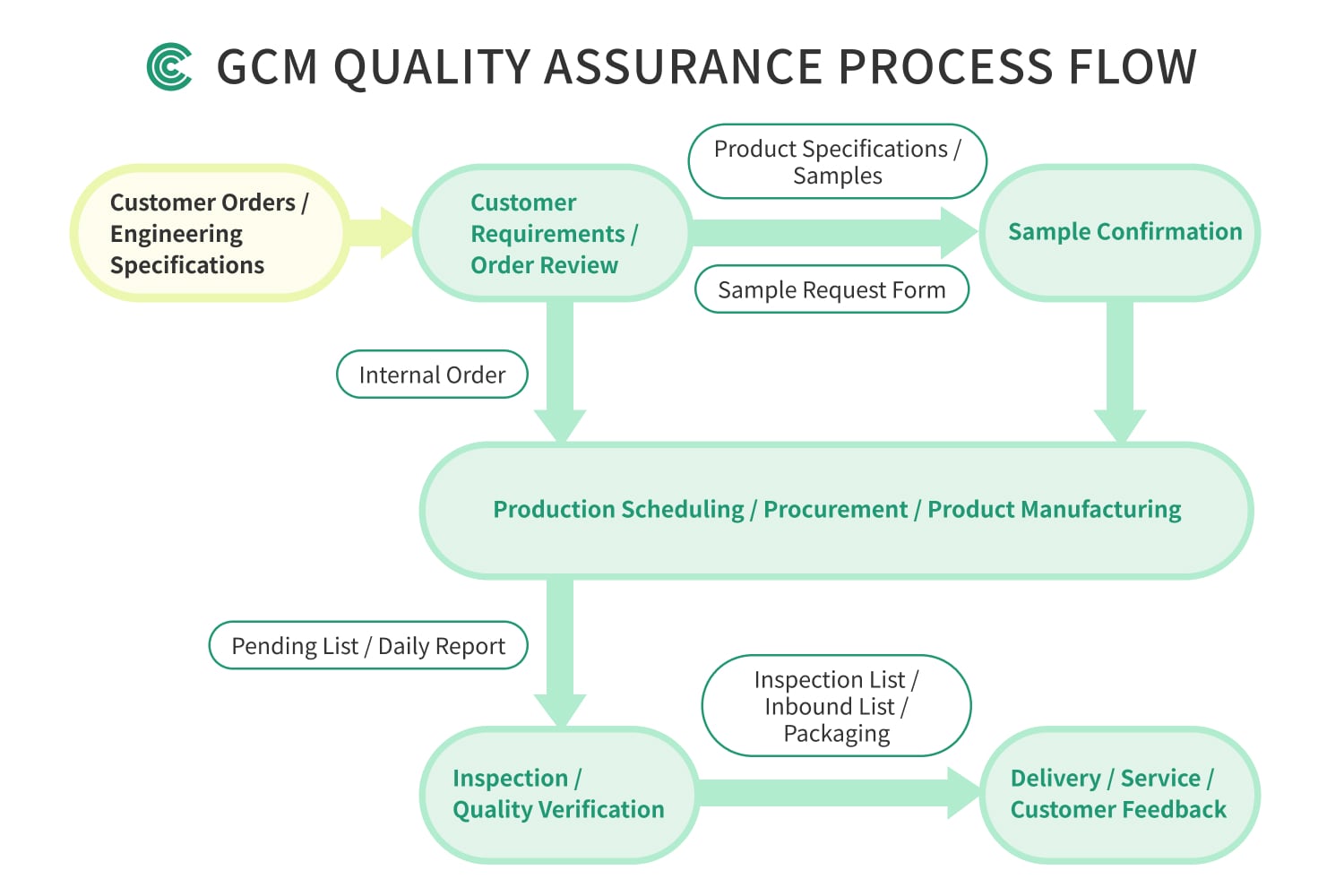

GCM fully understands that trust and customer satisfaction are founded on superior product quality. Therefore, the company is committed to enhancing its quality management standards. Through a comprehensive quality assurance process, GCM collaborates with relevant departments to establish and implement internal processes and policies related to product development, further ensuring product quality and consistency. In addition, relevant operational procedures have been formulated to support these goals, including finished goods material storage and handling procedures, order processing guidelines, and subcontractor evaluation protocols.

The company adheres to stringent standards in raw material procurement, production process monitoring, and product inspection and testing to ensure products meet the highest quality standards. These rigorous quality assurance measures not only improve production efficiency and reduce defect rates but also maintain GCM’s market competitiveness and earn customer trust.

GCM also continuously pursues technological innovation and talent development to enhance product performance and meet the diverse needs of customers, aiming to stay at the forefront of the industry. The company promotes the ISO 9001:2015 Quality Management System, supplemented by initiatives such as 6S, standardization, and employee training programs to strengthen organizational operations, improve product quality, and enhance overall competitiveness.

Internally, the company encourages continuous improvement to optimize quality management processes. Regular audits are conducted on existing procedures, and improvements are made based on the audit findings. A PDCA (Plan-Do-Check-Act) cycle-based quality management model is adopted to ensure a robust product quality control system.

To ensure that all employees uphold GCM’s high standards for product quality, the company offers a range of training courses for relevant staff. Upon completion of the courses, employees are expected to apply what they have learned to their daily work, thereby ensuring that product quality consistently meets the highest standards.

We have successfully implemented the ISO 9001 Quality Management System and the FSSC 22000 Food Safety Management System to ensure that our product quality consistently meets customer expectations. The company strictly adheres to food hygiene standards, carefully selects qualified coating suppliers, and fully enforces food safety management practices. While ensuring food safety, GCM continues to expand its business presence and is committed to achieving the dual goals of environmental sustainability and workplace health and well-being.

In addition, the company has adopted the P-D-C-A (Plan-Do-Check-Act) cycle-based quality management system, which is widely applied to improve product quality and production processes. In the P (Plan) phase, product improvement goals and reliability targets are defined, and responsibilities are appropriately assigned across departments. In the D (Do) phase, the plan is implemented and sufficient information is collected to support comprehensive evaluation. During the C (Check) phase, the execution results are reviewed and improvement measures are proposed for any shortcomings. Finally, in the A (Act) phase, the check plan is carried out and reassessed, with efforts made to narrow the gap between goals and outcomes. Through the implementation of this system, the company aims to enhance and stabilize product quality, delivering a superior product experience to our customers.

Our main products, including aluminum cans, steel cans, and metal ends, meet the recyclability standards defined under the Resource Recycling and Reuse Act and the Ministry of Environment’s designated list of “mandatory recyclable items.”

Internally, we adhere to the Resource Recycling and Reuse Act, the “Standards for Restricted Excessive Packaging of Goods,” and the Ministry of Environment’s guidelines for packaging reduction. We follow the principle of packaging optimization to achieve minimal material usage while ensuring product safety, hygiene, and consumer acceptance.